ANKER has launched the MFi USB-C to Lightning data cable in China and is also the first brand to sell the MFi USB-C to Lightning data cable in stock in China. The name of this cable is ANKER Powerline II C to Lightning. Today, I will disassemble it for you to see how the internal materials are.

1. ANKER Powerline II C to Lightning out of the box

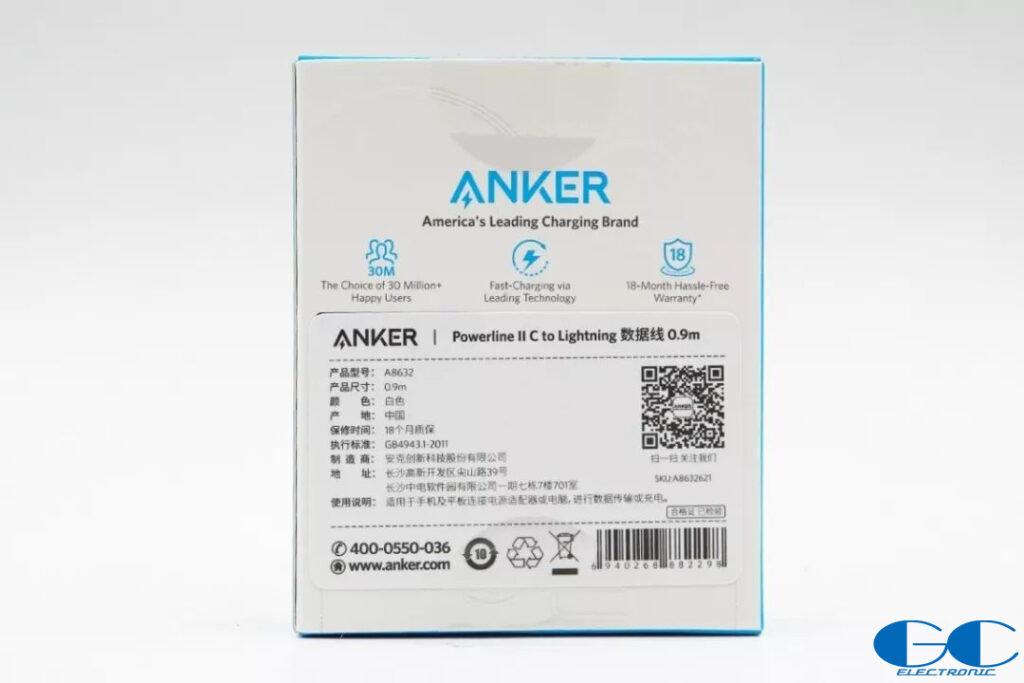

The main base color of the ANKER Powerline II C to Lightning data cable box is white + blue, with the “ANKER” brand logo and Apple MFi certified logo printed on the front, as well as the product model: A8632.

The relevant parameters of the data cable are printed on the back of the package.

Os parâmetros detalhados do cabo de dados são: Nome do produto: ANKER Powerline II C para cabo de dados Lightning 0,9M

Modelo: A8632

Tamanho: 0,9m

cor branca

Tempo de garantia: 18 meses de garantia

Instruções de uso: É adequado para conectar telefones celulares e tablets a adaptadores de energia ou computadores para transmissão ou carregamento de dados.

Ao desembalar, há um ANKER Powerline II C para o cabo de dados Lightning, uma braçadeira mágica e vários documentos em papel.

A camada externa branca do cabo de dados é feita de material TPE. A superfície do corpo do cabo é lisa e requintada e não há rebarbas óbvias. Parece mais macio na mão.

The interfaces at both ends of the data cable are Lightning (left) and USB-C (right). The connection between the cable end and the cable body is thickened and reinforced, and the length of the mesh tail is about 11mm to avoid bending and strain. The “ANKER” Logo is gravure on the end of the USB-C cable, and the SN code of the data cable is printed on the cable.

The SN code is: GD1910A8.

Close-up of USB-C interface pins, USB2.0 pins.

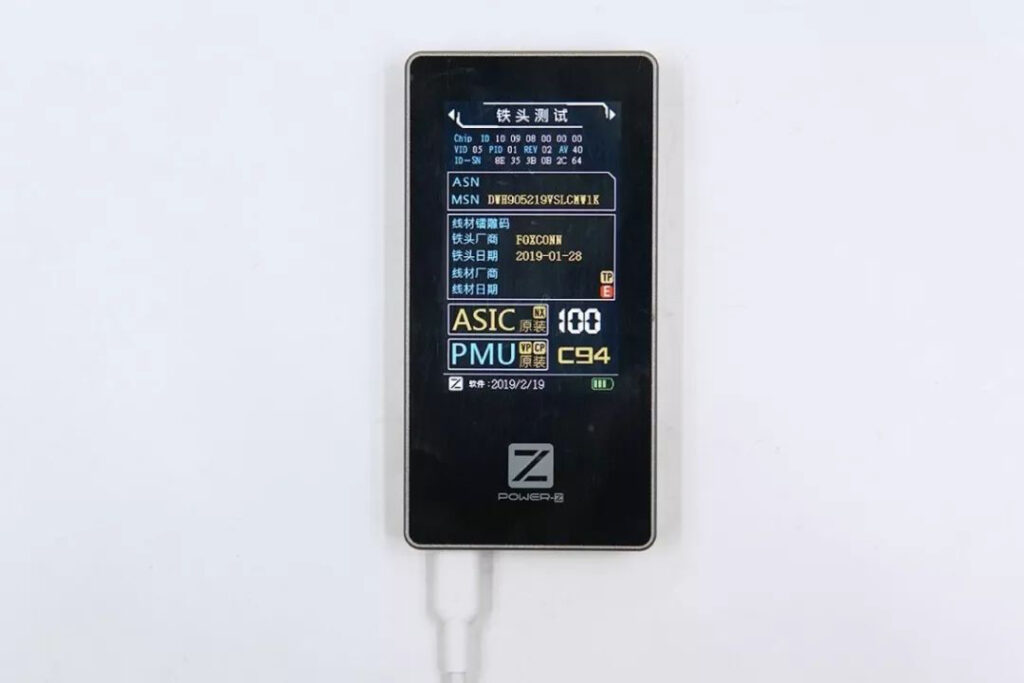

There are no patterns and words printed on this end of the Lightning connector, and the color of the terminal pins is silver, which conforms to the characteristics of C94 terminals.

Usando o testador ChargerLAB Power-Z MF001 para testar o terminal, verifica-se que o ASIC e o PMU do terminal são originais, o modelo do terminal é C94 e a pontuação é 100 em 100.

Comparado com o cabo USB-C para Lightning da Apple, a extremidade da malha da extremidade ANKER USB-C é um pouco mais longa e a camada externa é mais espessa e mais resistente a dobras.

A extremidade traseira do Lightning também é mais longa e mais grossa do que o cabo da Apple.

2. Desmontagem do cabo de dados ANKER Powerline II C para Lightning

O design da aparência e o acabamento do cabo de dados foram apresentados acima. Agora vamos desmontá-lo para ver como fica o interior do cabo de dados.

Cut the wire directly from the middle, the picture shows the cross-section of the ANKER Powerline II C to the Lightning data cable.

Cut the wire directly from the middle, the picture shows the cross-section of the ANKER Powerline II C to the Lightning data cable.

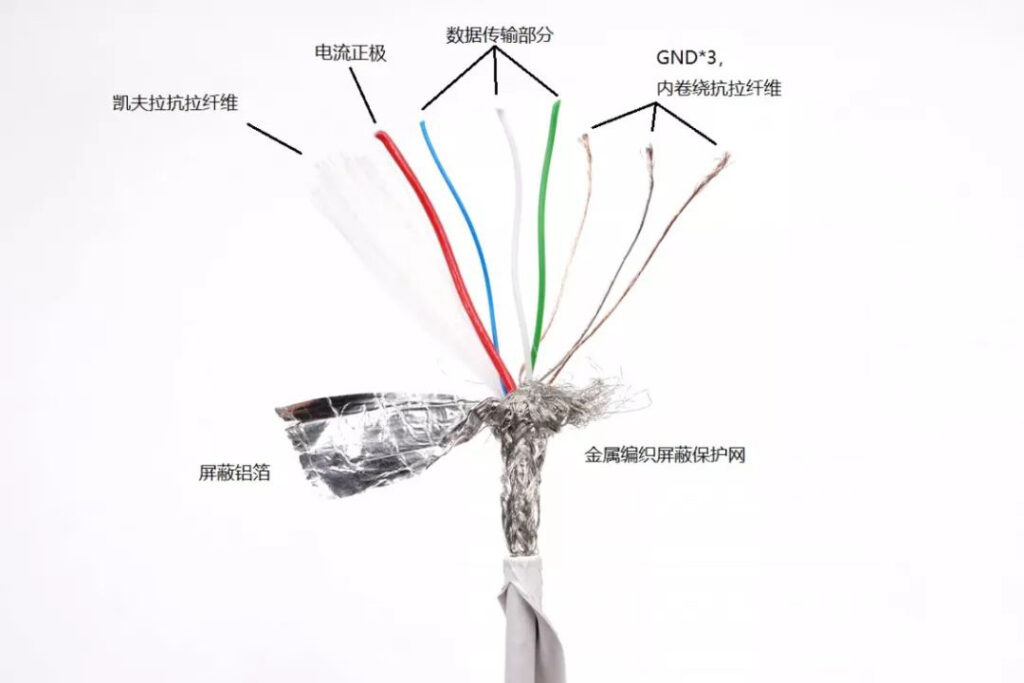

After the outer skin is peeled off, it can be seen that there is a layer of metal woven mesh inside, which has the function of shielding protection and stabilizing the woven mesh layer. The TPE outer skin and the metal woven mesh are very closely combined, and the bottom of the outer skin can be seen. pressed imprint.

Continue to disassemble the metal braided mesh, below is a layer of shielding aluminum foil to enhance the shielding effect.

After removing the aluminum foil shield, you can see the core part.

The structure of the core part is listed.

A linha vermelha é espessada para garantir a capacidade de transmissão de energia. Ele usa 3 fios de fibra elástica Kevlar para combinar com outros núcleos por torção, o que pode efetivamente melhorar o desempenho anti-tração e reduzir o atrito entre os núcleos internos. O efeito final Ou seja, o fio é puxado continuamente, grosso, mas não duro. Percebe-se que o número de fibras é muito grande ao quebrar todas as fibras. De modo geral, devido a considerações de custo, a maioria das marcas não utiliza uma quantidade tão grande de fibras elásticas. ANKER está disposta a empilhar materiais para garantir durabilidade.

Os detalhes da desmontagem do fio são mostrados na figura.

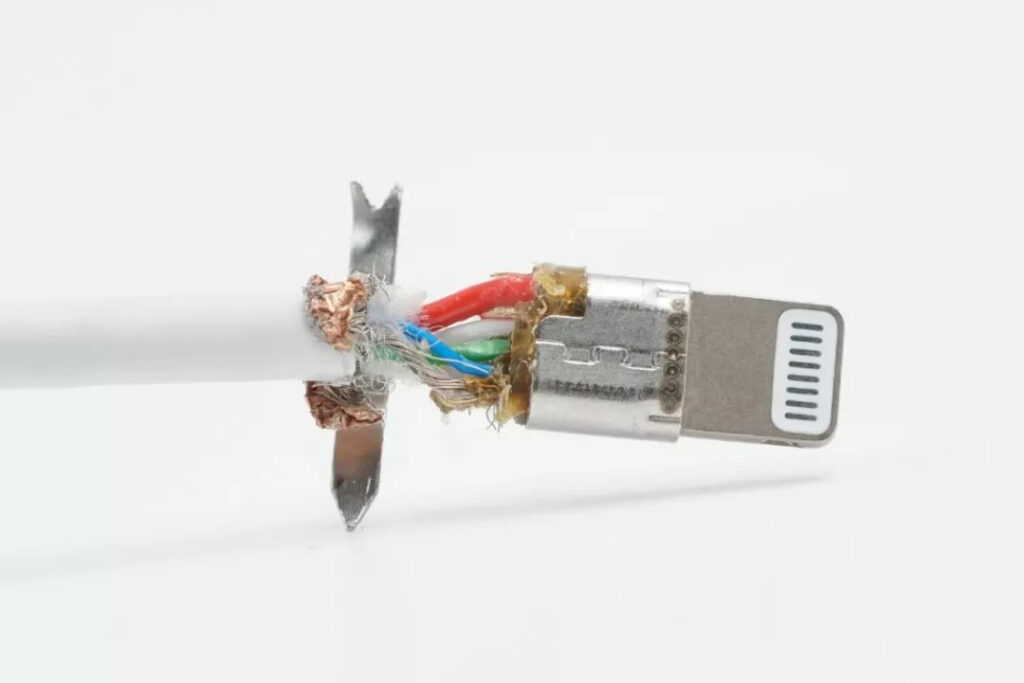

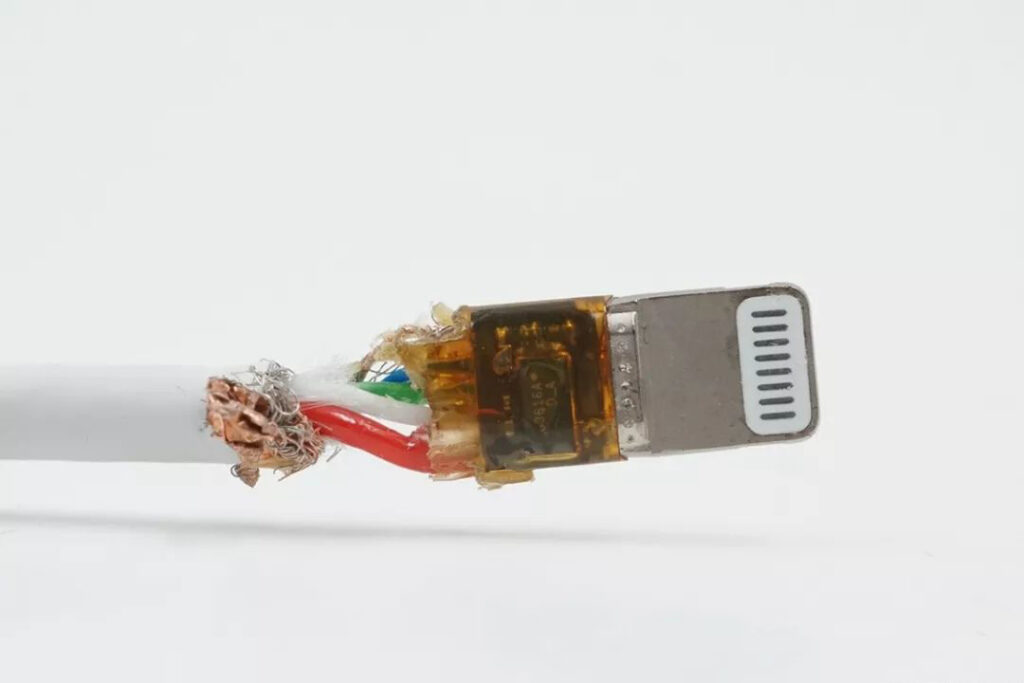

After reading the wire part, it is the turn of the Lightning plug end to disassemble, peel off the outer skin, and inside is a layer of amber translucent structural protective glue.

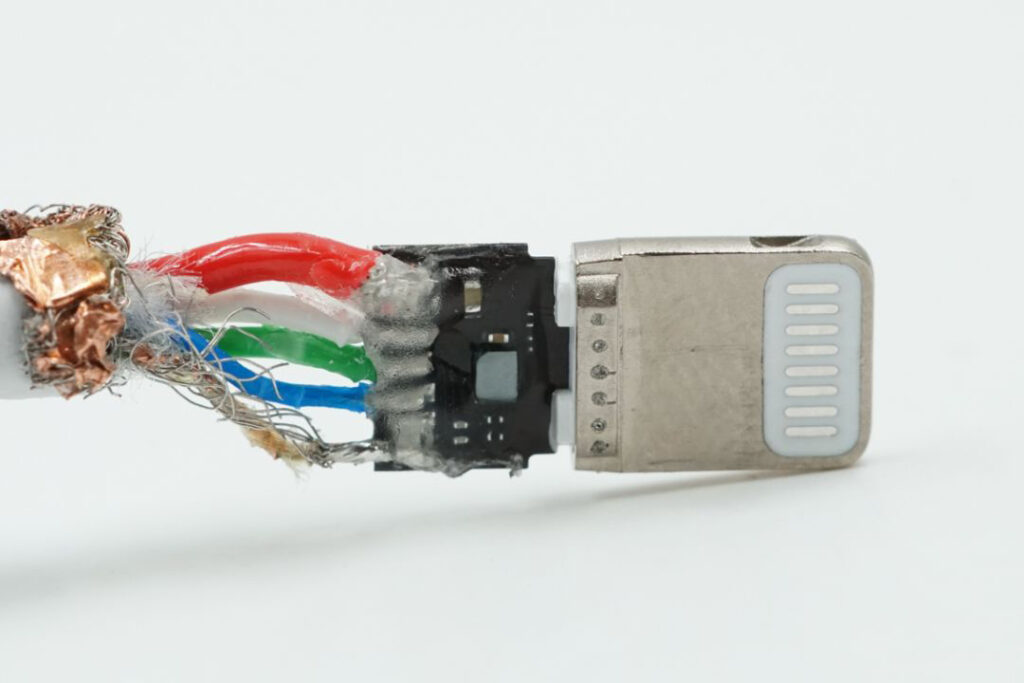

Remove the amber structural protective glue, you can see that the steel sleeve and the metal base are connected and fixed by spot welding, and the welding points are uniform and firm. Then pick up the cold-pressed terminal of the wire core at the end of the steel sleeve to expose the inner wire core, aluminum foil shield, and tensile fiber.

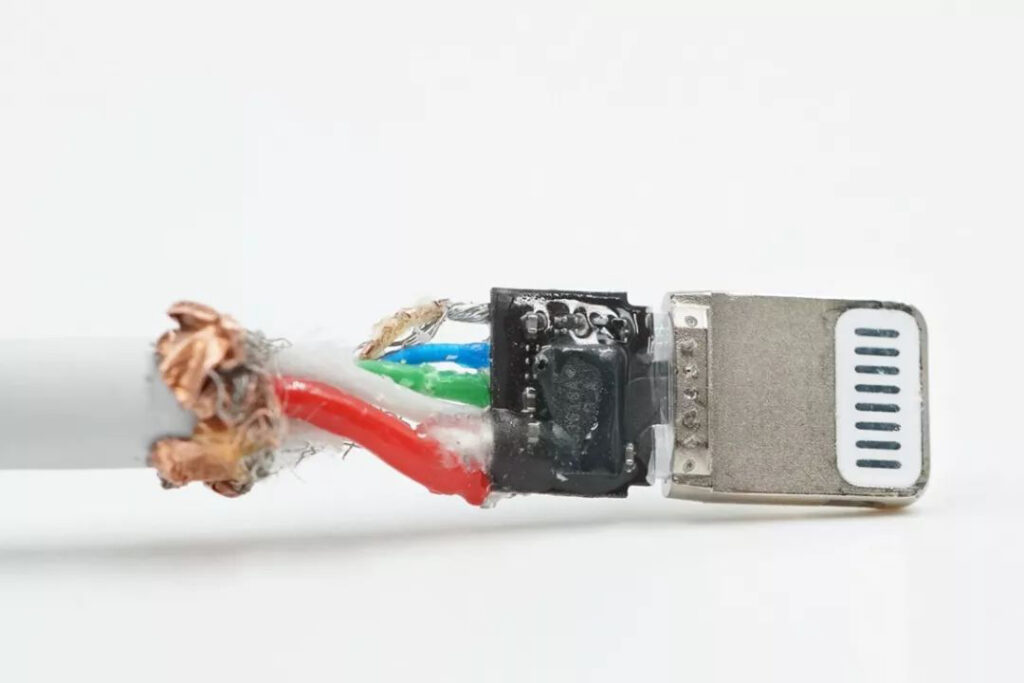

After removing the steel sleeve, it can be seen that the structural protective glue has also penetrated into the interior, and all components such as PCBA, wire core, and steel shell are glued into a whole, and it can also be insulated and moisture-proof.

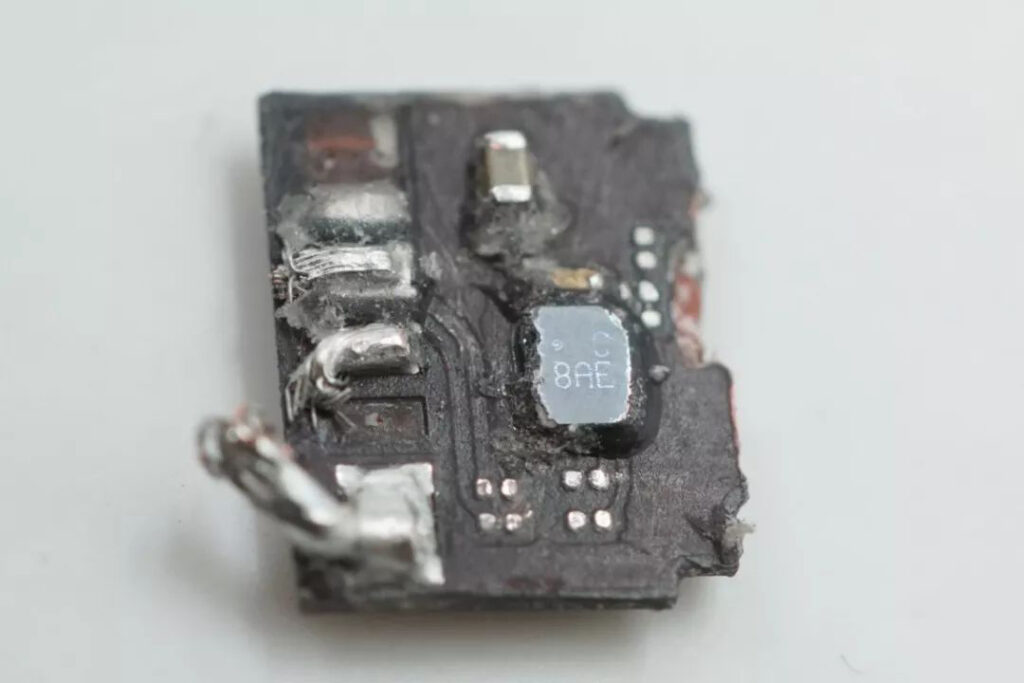

The chip leaked out after all the structural protective glue was removed.

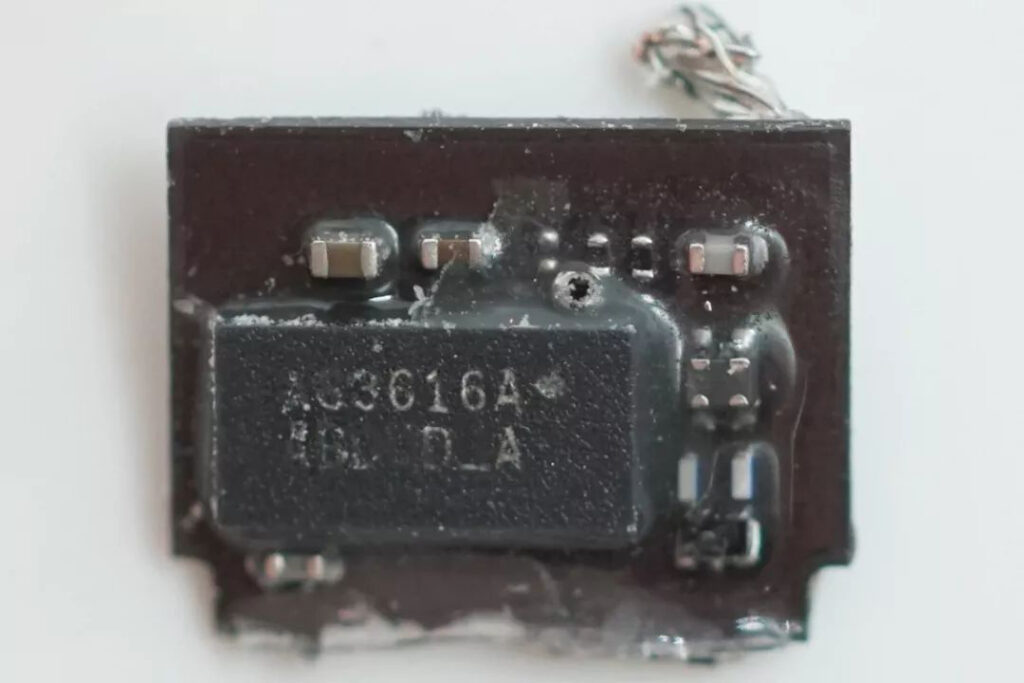

The surface of the chip is silk-screened A63616A, which is an Apple C94 terminal chip. Compared with the previous USB-A interface that uses multiple components combined with C48 and E75 terminal chips, the C91 and C94 chips of the USB-C interface are designed to be more integrated and can support USB PD fast charging. C91 is used by Apple’s own cables and is not available for sale. C94 is supplied by Apple to third-party brands. There is no difference in performance between the two.

On the other side of the PCB, there is a silver mirror main chip.

The laser silk screen is a very small G, with a capital C above and 8AE below.

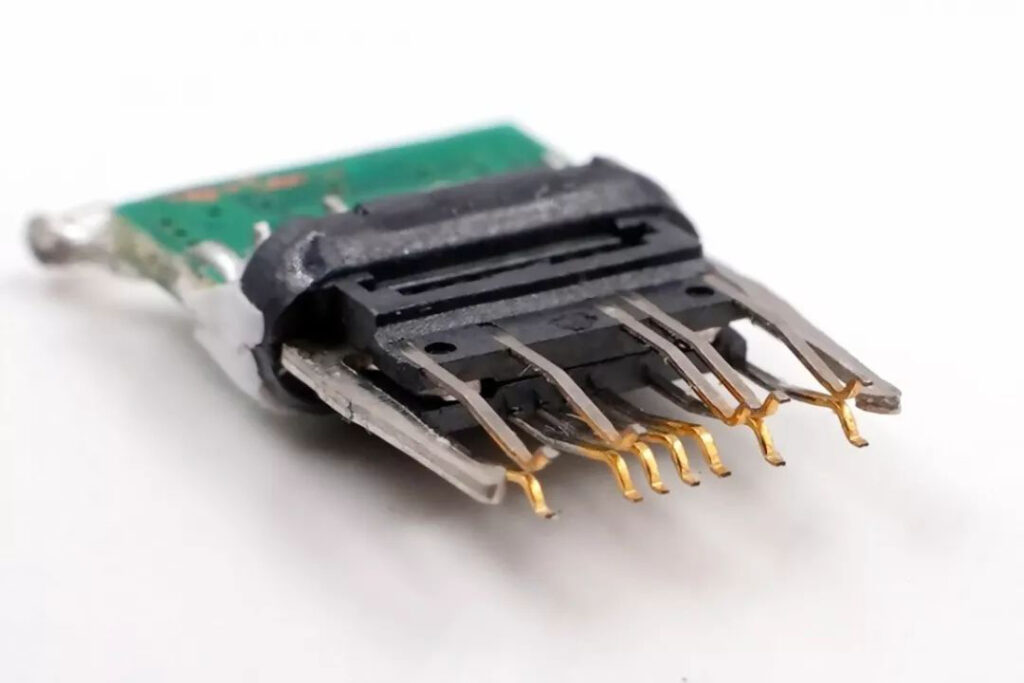

Let’s take a look at the end of the USB-C port. The outer skin is peeled off to expose the steel sleeve. The end of the steel sleeve is also a cold-pressed terminal for compressing the wire.

The steel sleeve is cut open, and it is also the overall glue injection. The USB-C PCB is only used to connect the wires and does not use the chip. The functions are all completed by the chip on the Lightning end.

The contact part of the USB-C interface is gold-plated, and the locking mechanism at the left and right end is strong and powerful.

3. Summary of GCC Electronic

O cabo de dados ANKER Powerline II C para Lightning é feito de material TPE, a superfície é lisa sem rebarbas óbvias e o acabamento é excelente. O corpo da linha é mais grosso que o original da Apple e parece flexível e não duro. Além disso, a conexão entre o corpo do fio e a cabeça do fio também é reforçada, a cauda da rede é alongada e espessada e a resistência à flexão é muito boa.

After dismantling, it was found that the metal braided shielding layer + aluminum foil shielding layer was used inside the cable body to enhance anti-interference, and 3 strands of tensile fiber and the wire core were mixed and twisted, so that the data cable had a very strong anti-pulling ability, and reduced the wire The friction between the cores keeps the wire flexible. The core of the current transmission line adopts a bold design, and the use of 3 strands for GND can also avoid being too hard.

The Lightning end of the data cable is designed with structural adhesive as a whole. The internal use of the Apple C94 certification chip, the integration is extremely high.

In general, the ANKER Powerline II C to Lightning data cable is in the style of a big manufacturer in terms of workmanship and materials. It is worth paying for in terms of materials and details. Although its price is not the cheapest, it is worth every penny. The principle of distributing goods can be concluded in this dismantling article, and friends who pursue quality and durability should not miss it.