ANKER ha lanciato il cavo dati MFi da USB-C a Lightning in Cina ed è anche il primo marchio a vendere il cavo dati MFi da USB-C a Lightning in stock in Cina. Il nome di questo cavo è ANKER Powerline II C to Lightning. Oggi lo smonterò per farti vedere come sono i materiali interni.

1. ANKER Powerline II C a Lightning pronto all'uso

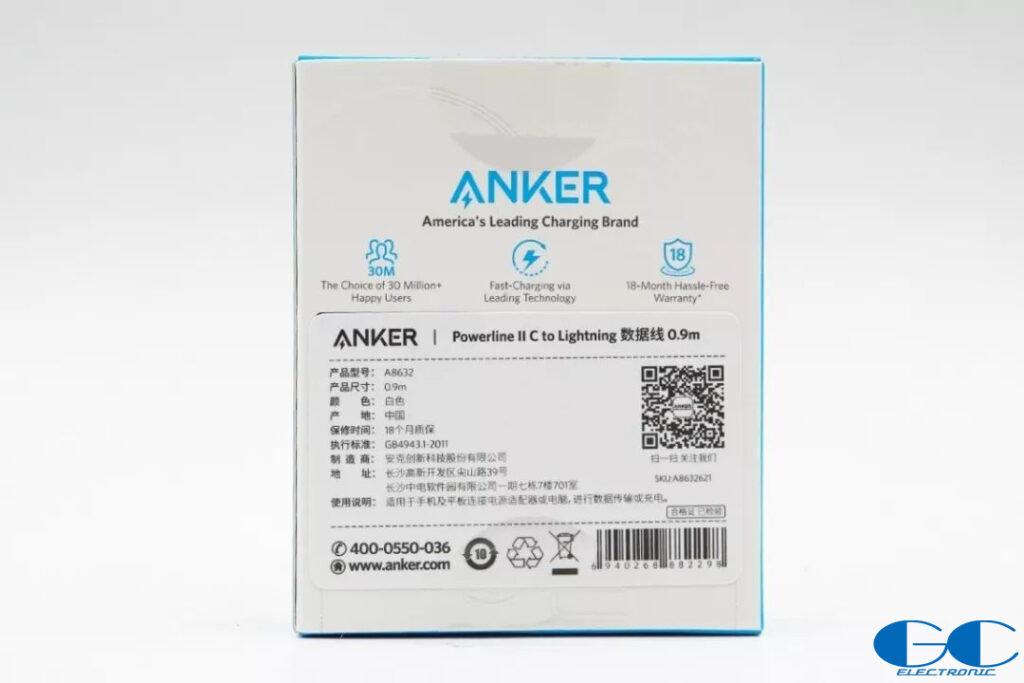

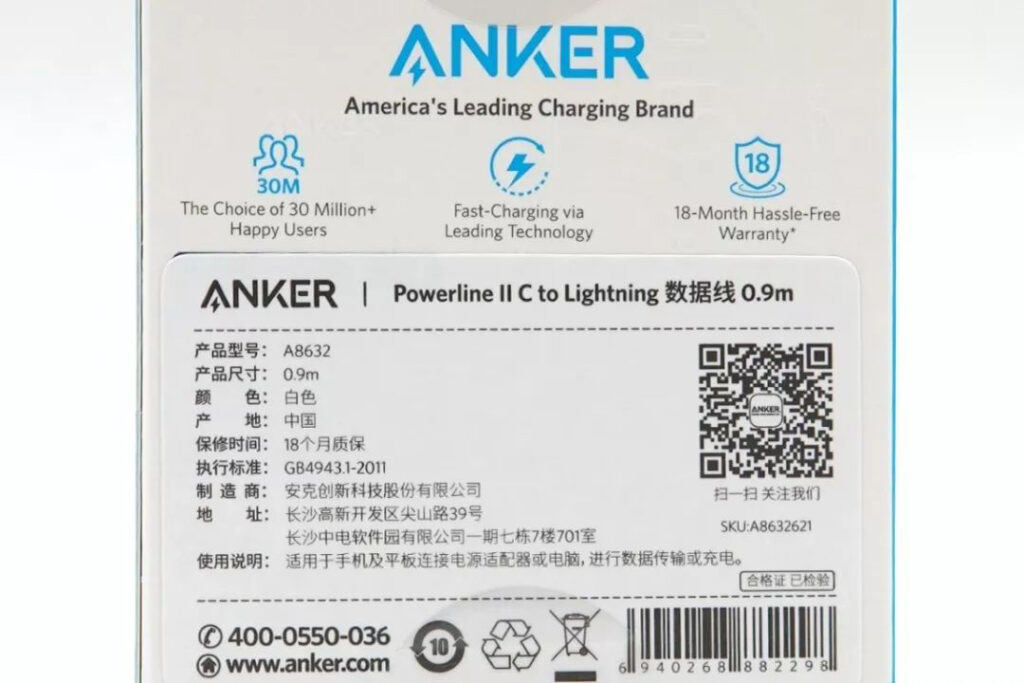

Il colore di base principale del box per cavi dati ANKER Powerline II da C a Lightning è bianco + blu, con il “ANKER” logo del marchio e logo certificato Apple MFi stampati sul davanti, così come il modello del prodotto: A8632.

I parametri rilevanti del cavo dati sono stampati sul retro della confezione.

I parametri dettagliati del cavo dati sono: Nome del prodotto: ANKER Powerline II C al cavo dati Lightning 0.9M

Modello: A8632

Dimensioni: 0,9 m

colore bianco

Tempo di garanzia: 18 mesi di garanzia

Istruzioni per l'uso: è adatto per collegare telefoni cellulari e tablet ad adattatori di alimentazione o computer per la trasmissione o la ricarica dei dati.

Disimballando, c'è un ANKER Powerline II C per il cavo dati Lightning, una fascetta magica e più documenti cartacei.

La pelle esterna bianca del cavo dati è realizzata in materiale TPE. La superficie del corpo del cavo è liscia e raffinata e non ci sono sbavature evidenti. Si sente più morbido nella mano.

Le interfacce su entrambe le estremità del cavo dati sono Lightning (a sinistra) e USB-C (a destra). La connessione tra l'estremità del cavo e il corpo del cavo è ispessita e rinforzata e la lunghezza della coda della rete è di circa 11 mm per evitare flessioni e sollecitazioni. IL “ANKER” Il logo è inciso all'estremità del cavo USB-C e il codice SN del cavo dati è stampato sul cavo.

Il codice SN è: GD1910A8.

Primo piano dei pin dell'interfaccia USB-C, pin USB 2.0.

Non ci sono motivi e parole stampate su questa estremità del connettore Lightning e il colore dei pin del terminale è argento, che è conforme alle caratteristiche dei terminali C94.

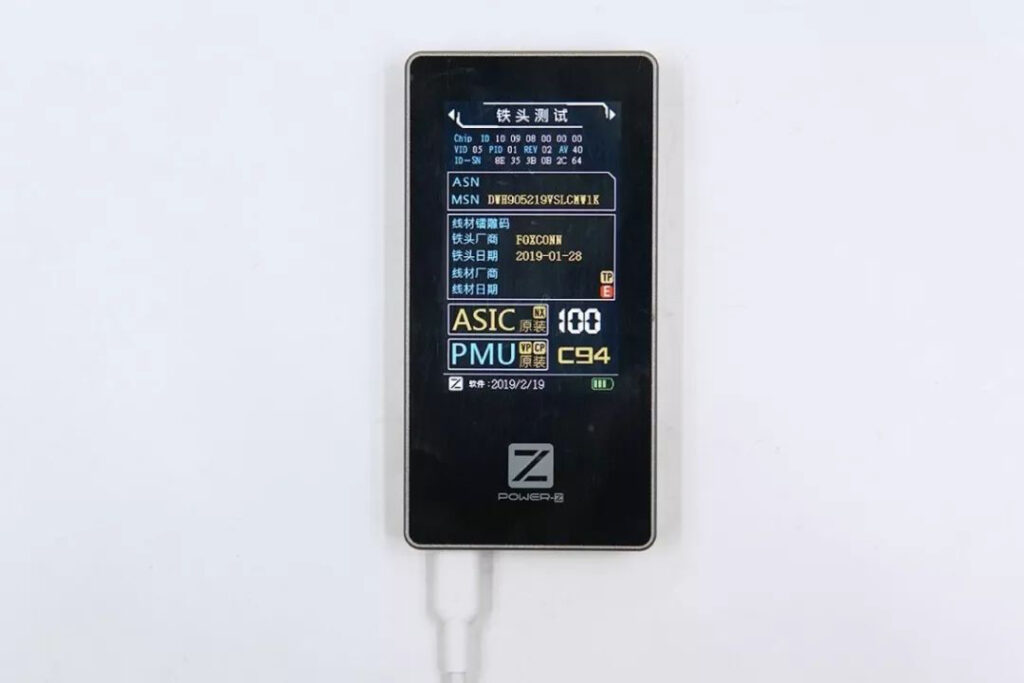

Using ChargerLAB Power-Z MF001 tester to test the terminal, it is found that the ASIC and PMU of the terminal are original, the terminal model is C94, and the score is 100 out of 100.

Compared with the Apple USB-C to Lightning cable, the mesh end of the ANKER USB-C end is slightly longer, and the outer skin is thicker and more resistant to bending.

The tail end of the Lightning end is also longer and thicker than the Apple cable.

2. ANKER Powerline II C to Lightning data cable dismantling

The appearance design and workmanship of the data cable have been introduced above. Now we will dismantle it to see what the inside of the data cable looks like.

Cut the wire directly from the middle, the picture shows the cross-section of the ANKER Powerline II C to the Lightning data cable.

Cut the wire directly from the middle, the picture shows the cross-section of the ANKER Powerline II C to the Lightning data cable.

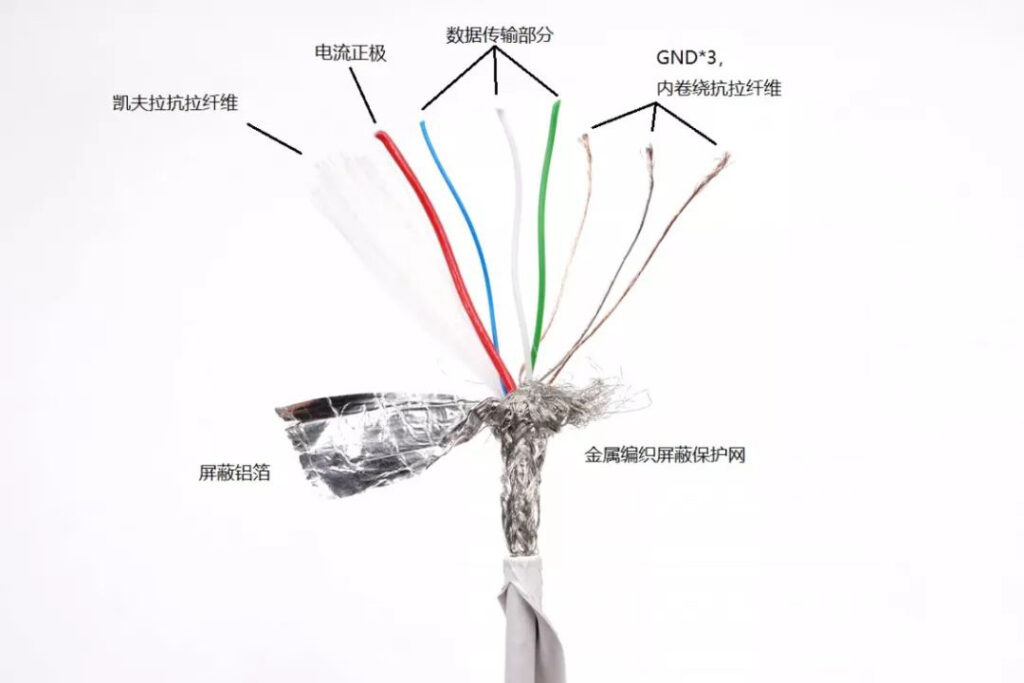

After the outer skin is peeled off, it can be seen that there is a layer of metal woven mesh inside, which has the function of shielding protection and stabilizing the woven mesh layer. The TPE outer skin and the metal woven mesh are very closely combined, and the bottom of the outer skin can be seen. pressed imprint.

Continue to disassemble the metal braided mesh, below is a layer of shielding aluminum foil to enhance the shielding effect.

After removing the aluminum foil shield, you can see the core part.

The structure of the core part is listed.

The red line is thickened to ensure the power transmission capacity. It uses 3 strands of Kevlar tensile fiber to combine with other cores by twisting, which can effectively improve the anti-pull performance and reduce the friction between the inner cores. The final effect That is, the wire is pulled continuously, thick but not hard. It can be seen that the number of fibers is very large by breaking up all the fibers. Generally speaking, due to cost considerations, most brands do not use such a large amount of tensile fibers. ANKER is willing to stack materials to ensure durability.

The wire disassembly details are shown in the figure.

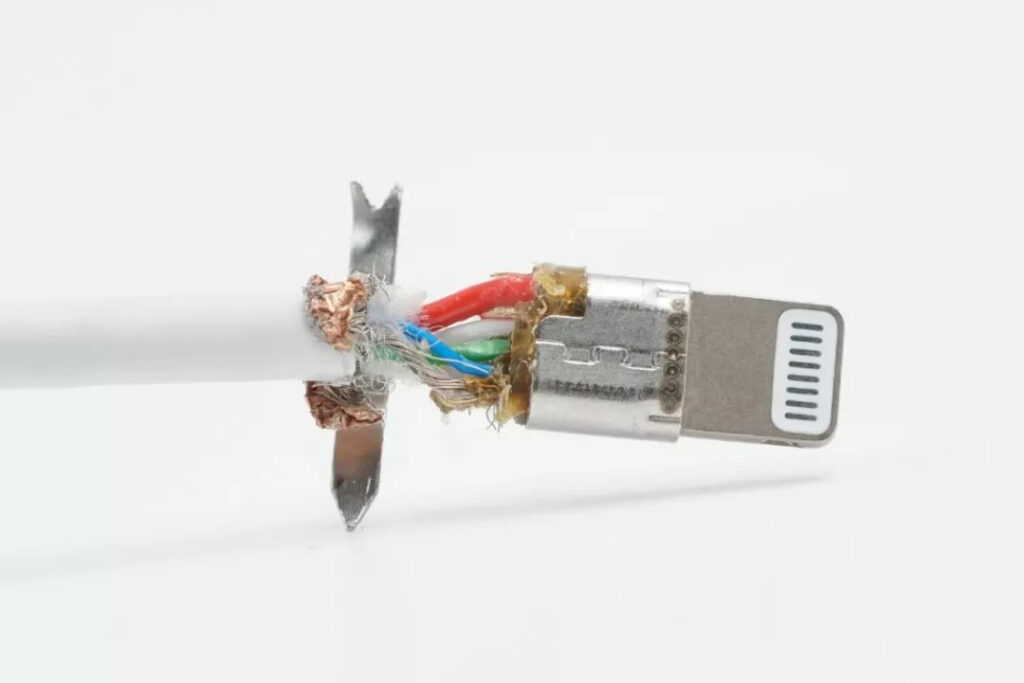

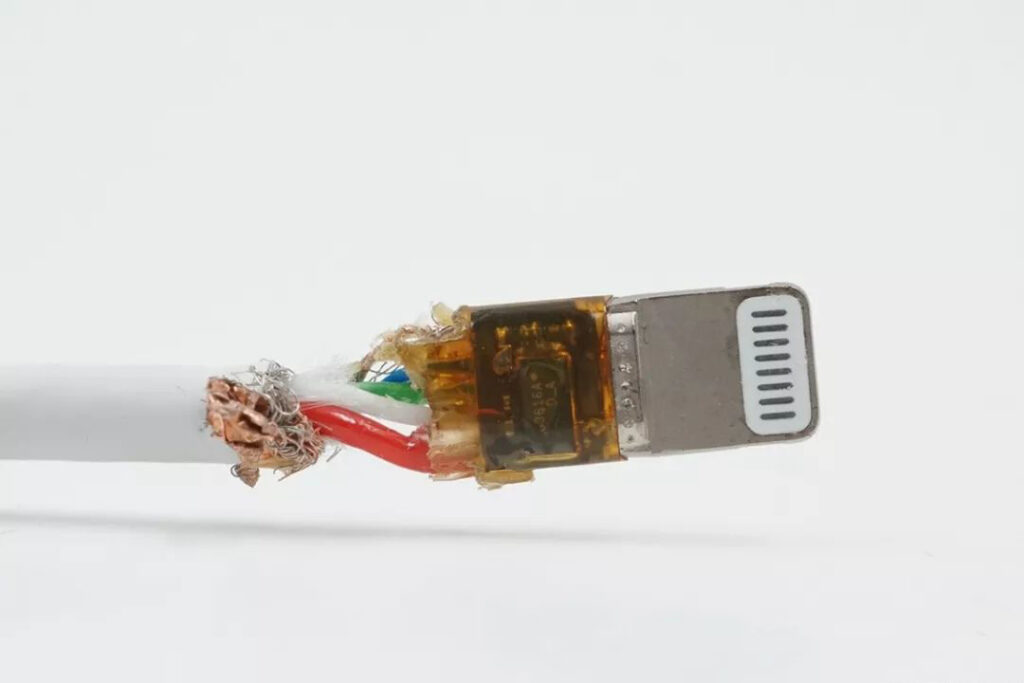

Dopo aver letto la parte del filo, è il turno dell'estremità della spina Lightning da smontare, staccare la pelle esterna e all'interno c'è uno strato di colla protettiva strutturale traslucida color ambra.

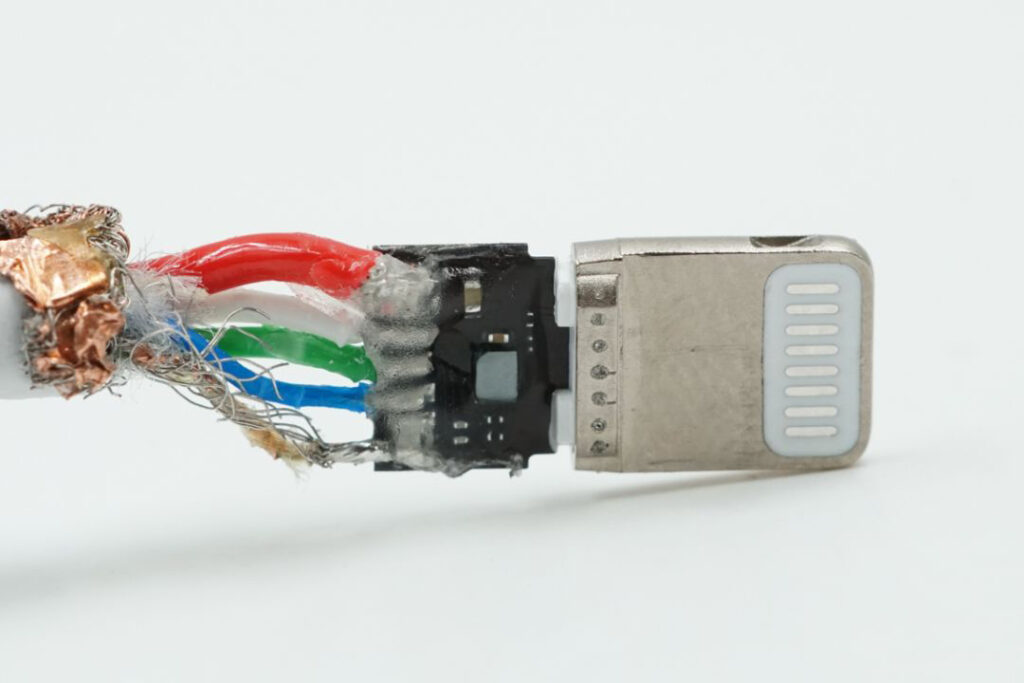

Rimuovi la colla protettiva strutturale color ambra, puoi vedere che il manicotto in acciaio e la base in metallo sono collegati e fissati mediante saldatura a punti e che i punti di saldatura sono uniformi e fermi. Quindi raccogliere il terminale pressato a freddo dell'anima del filo all'estremità del manicotto in acciaio per esporre l'anima interna del filo, lo schermo in lamina di alluminio e la fibra di trazione.

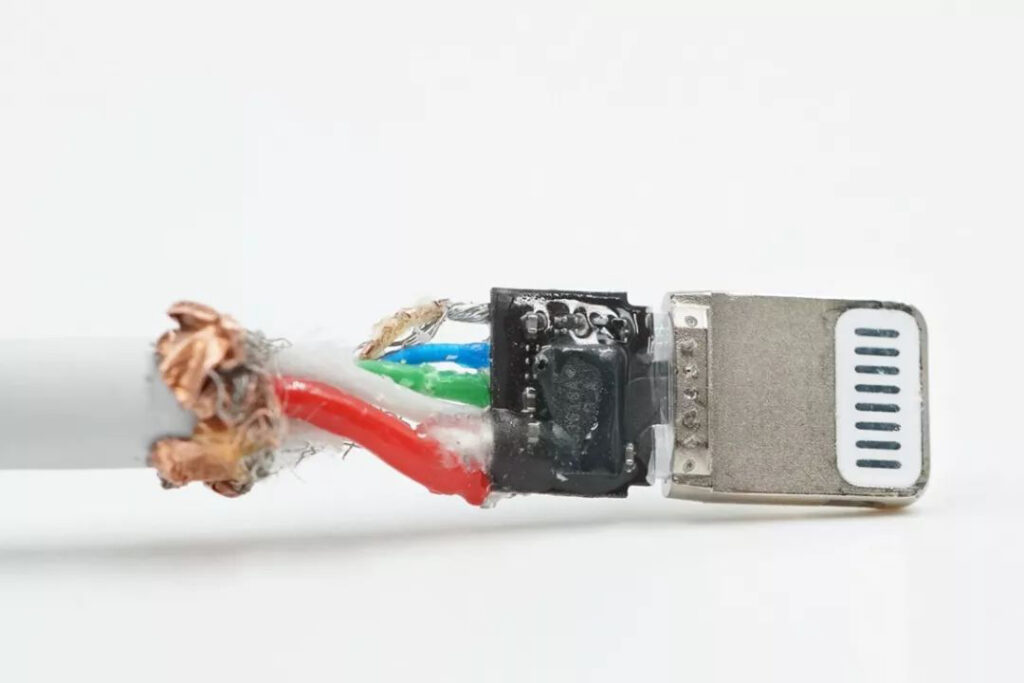

After removing the steel sleeve, it can be seen that the structural protective glue has also penetrated into the interior, and all components such as PCBA, wire core, and steel shell are glued into a whole, and it can also be insulated and moisture-proof.

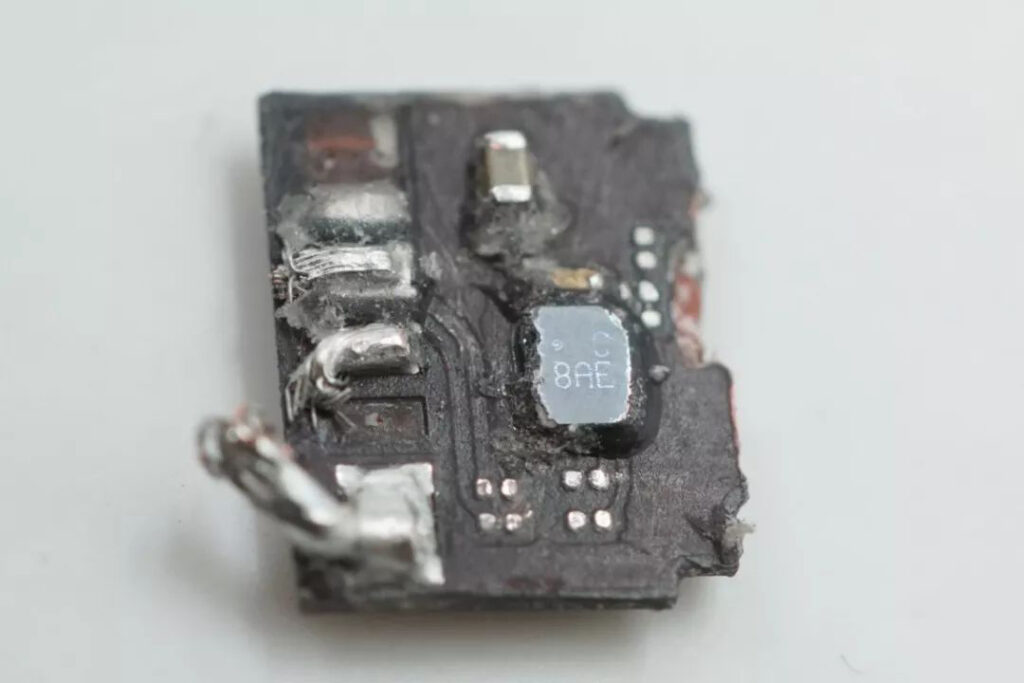

The chip leaked out after all the structural protective glue was removed.

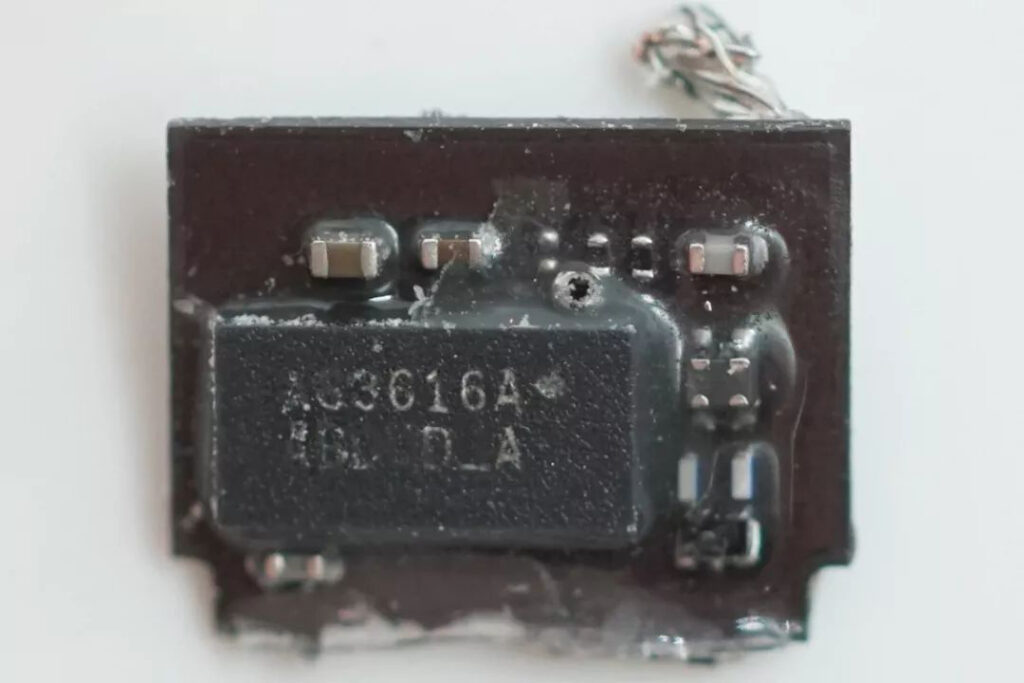

The surface of the chip is silk-screened A63616A, which is an Apple C94 terminal chip. Compared with the previous USB-A interface that uses multiple components combined with C48 and E75 terminal chips, the C91 and C94 chips of the USB-C interface are designed to be more integrated and can support USB PD fast charging. C91 is used by Apple’s own cables and is not available for sale. C94 is supplied by Apple to third-party brands. There is no difference in performance between the two.

On the other side of the PCB, there is a silver mirror main chip.

The laser silk screen is a very small G, with a capital C above and 8AE below.

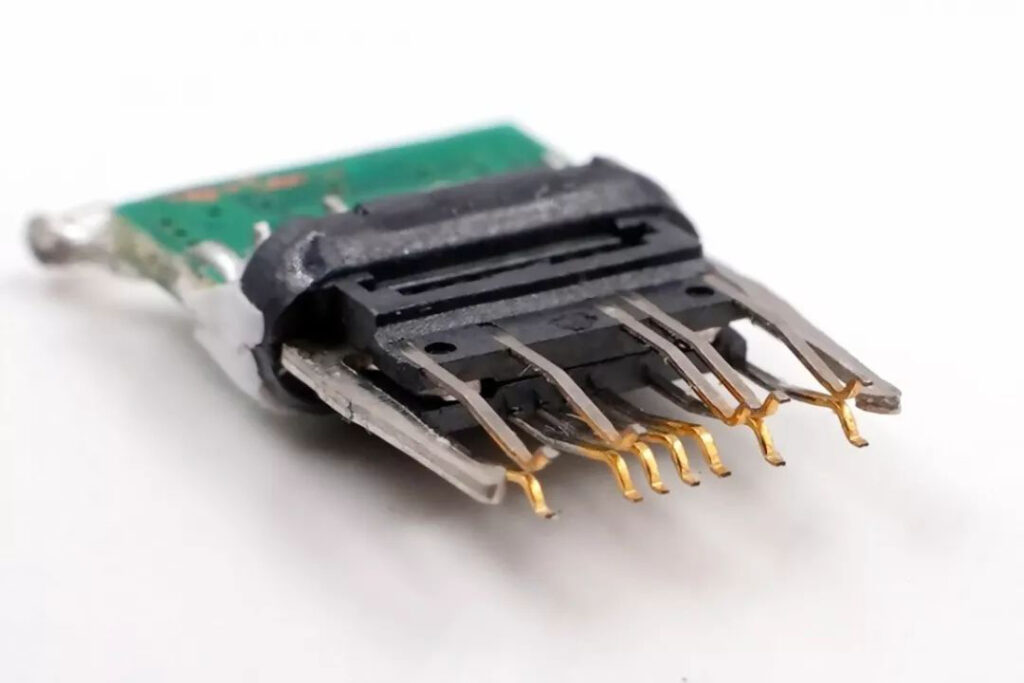

Let’s take a look at the end of the USB-C port. The outer skin is peeled off to expose the steel sleeve. The end of the steel sleeve is also a cold-pressed terminal for compressing the wire.

The steel sleeve is cut open, and it is also the overall glue injection. The USB-C PCB is only used to connect the wires and does not use the chip. The functions are all completed by the chip on the Lightning end.

The contact part of the USB-C interface is gold-plated, and the locking mechanism at the left and right end is strong and powerful.

3. Summary of GCC Electronic

The ANKER Powerline II C to Lightning data cable is made of TPE material, the surface is smooth without obvious burrs, and the workmanship is excellent. The line body is thicker than Apple’s original, and it feels flexible and not hard. In addition, the connection between the wire body and the wire head is also reinforced, the tail part of the net is lengthened and thickened, and the bending resistance is very good.

After dismantling, it was found that the metal braided shielding layer + aluminum foil shielding layer was used inside the cable body to enhance anti-interference, and 3 strands of tensile fiber and the wire core were mixed and twisted, so that the data cable had a very strong anti-pulling ability, and reduced the wire The friction between the cores keeps the wire flexible. The core of the current transmission line adopts a bold design, and the use of 3 strands for GND can also avoid being too hard.

The Lightning end of the data cable is designed with structural adhesive as a whole. The internal use of the Apple C94 certification chip, the integration is extremely high.

In general, the ANKER Powerline II C to Lightning data cable is in the style of a big manufacturer in terms of workmanship and materials. It is worth paying for in terms of materials and details. Although its price is not the cheapest, it is worth every penny. The principle of distributing goods can be concluded in this dismantling article, and friends who pursue quality and durability should not miss it.